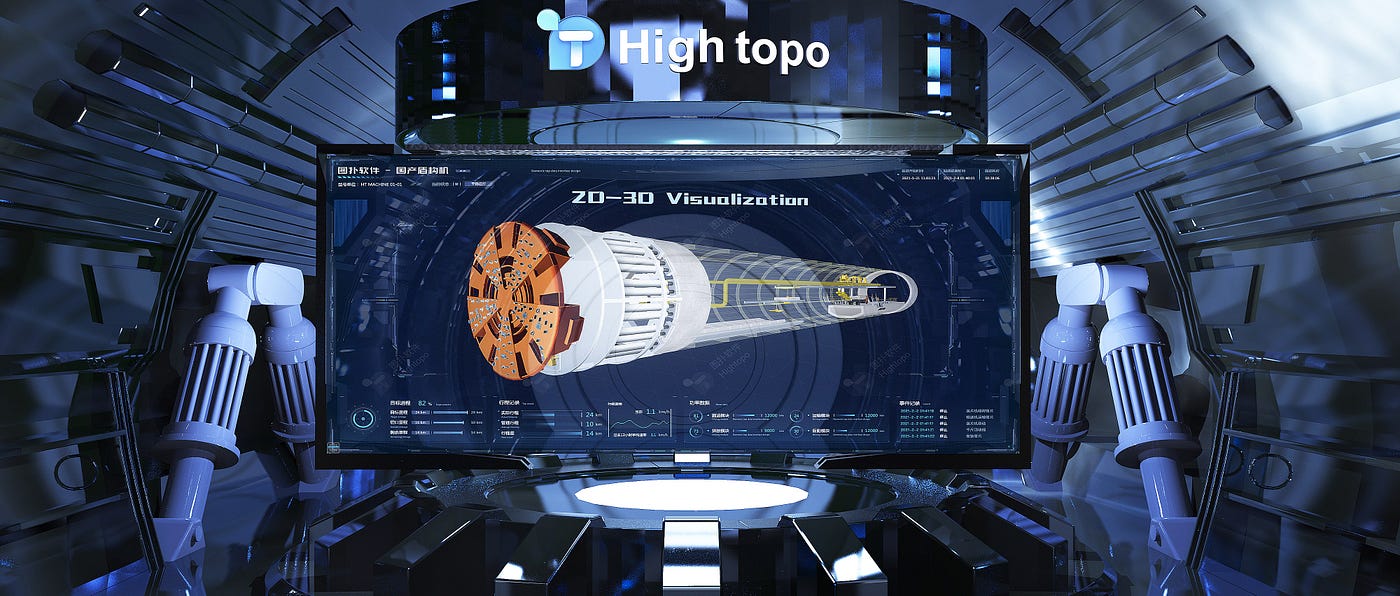

Meet the giant tunnel boring machines with 3d model and 3d animation

Click the picture to check full video

A tunnel boring machine (TBM), also known as a “mole”, is a machine used to excavate tunnels with a circular cross-section through a variety of soil and rock strata.

How It Works

The first part of the TBM work is the tunneling phase. The TBM has a cutting wheel which is pressed against the tunnel face by hydraulic cylinders. Inside the cutting wheel, the disc cutters and scraping tool loosen the material.

If the earth is unstable and to stop the tunnel face collapsing or digging too fast, the TBM uses the soil that has already been dug out by the cutting wheel to support the tunnel face. This creates a stable environment for the tunneling to move forward.

The tunneling face is continuously monitored by pressure sensors. They check the turning power of the cutting wheel and the screw conveyor and they also keep track of the material that has been excavated.

The material is then taken away on conveyor belts.

Once the tunneling phase is done the cutting face and the screw conveyor are stopped and the ring building phase starts.

A complete tunnel ring consists of several linning segments made of pre-build reinforced concrete. They must match the exact size required and are taken into the tunnel on flatbed rail.

The concrete segments are fed by the concrete feeder and lifted into place using a vacuum. The hydraulic cylinders are temporarily retracted in order to provide enough space for the new segment. The segments are positioned with millimeter precision and held in place by cylinders before being finally bolted into position. The conical keystone is put in from the front to complete the lining ring.

During all this work, people and the machines are protected by the shield skin from the saturated ground, where water is under pressure.

All the readings are displayed and fed back to the machine operator.

Combined with real-time monitoring of HT's data visualization panel, various data indicators of the construction process are displayed in real-time. Intelligent analysis and collection of back-end data truly reflect the real-time dynamics of each module, allowing managers to understand the situation of each section and perform quick maintenance and management.

Why Hightopo Visualization?

Traditional construction often uses BIM models, but the BIM modeling often too large in terms of data size and the model itself is not beautiful enough.

Our visualization solution not only improves the work efficiency of the construction site but also monitors the progress of the project in real-time.

In this case study, we compared the traditional modeling and Hightopo’s light-weight visualization solution. Hightopo’s web-based 3D visualization has a more flexible and vivid effect. And this will enable customers to understand quickly how the product work and the product advantage so that to gain an actionable insight.

The light-weight web-based solution requires no plugins or downloads, it just works seamlessly on any modern browser & device.

The light-weight web-based solution requires no plugins or downloads, it just works seamlessly on any modern browser & device.

How We Can Help You

Hightopo specializes in physical simulation, industrial simulation, data visualization. Providing clients the one-stop data visualization solution from consulting, design, development to post-sales support.

We are a dedicated team devoted to web-based 2d & 3d computer graphics technology, with more than 10 years of proven industry experience, we are committed to bringing our visualization solution to the world.

Check our website for more industry visualization inspiration and explore new possibilities with us!