Smart Manufacturing: Visualize SMT Assembly Line

The manufacturing industry has undergone significant revolutions, now the industry is entering the exciting Industry 4.0. It’s a transition powered by data and automation technology that could transform every step of the manufacturing process. The goal is to drive productivity and innovation and empower businesses in an integrated, data-driven manufacturing environment.

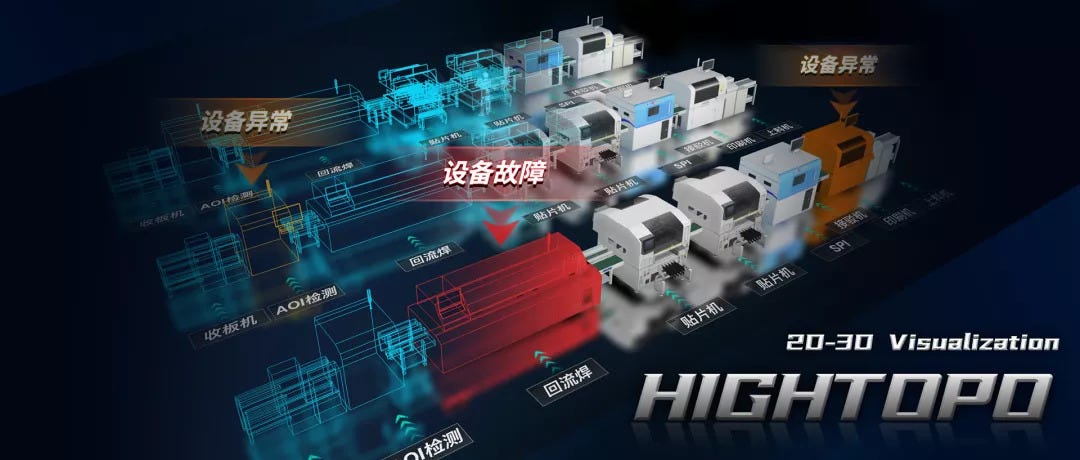

In this article, we illustrate the digital twin visualization system for an SMT assembling production line by the Hightopo 3D Visualization solution. Surface-mount technology (SMT) is a method for producing electronic circuits in which the components are mounted or placed directly onto the surface of printed circuit boards(PCBs).

By utilizing 3D models, users can visualize each piece of equipment, from screen printer, SPI machine, AOI machine, AGV, camera, fire safety equipment, AC and more. By connecting the IoT sensors, data can be collected and analysed and syn together in our visualization system.

Quality Data Visualization

Visualization dashboard — — Statistical Process Control(SPC) — — Quality data is collected and analysed that helps process engineers to improve the current process. The function allows for comparing data from the SPI and AOI systems to conduct parallel analysis. This makes it possible to identify and eliminate the causes of defects.

Assembling Line Visualization

A typical configuration for an SMT assembly process consists of the following automated machines connected in sequence: A Line Loader loads PCBs one-by-one from a stack onto the conveyor belt. A Screen Printer performs the application of the solder paste onto the board. Pick and Place machines select individual components from reels and place them onto the board. The boards are then forwarded to the Reflow Oven which consists of a conveyor belt moving inside a heated chamber. Here, the solder paste melts to form contacts.

Indoor Positioning System(IPS)

IPS refers to the technology that helps locate people and objects indoors. That location information is then fed into HT Visualization System to make the information useful.

Utilizing IoT 5G+, Bluetooth 5.0 and other technologies, and the help of intelligent base stations, wearable devices, the positioning coordinate data is transmitted to the front-end to illustrate the real-time positioning function of personnel and AGV cars. And HT also supports the drawing of historical running trajectories, which help managers analyze the rationality of the production line layout and make corresponding adjustments in time.

Surveillance Video Integration

HT uses the actual position of the on-site camera as a reference and places the model at the corresponding position in the 3D scene to simulate the real world scenario to solve the common issue regarding video surveillance integration and enhancing the value of video applications. Furthermore, use emerging video fusion technology to seamlessly embed video into the scene to truly restore the real scene of the scene.

Conclusion

With modern tools and simulations, new products are first produced virtually these days — offline on a digital twin of your SMT lines, without tests, and without having to interrupt valuable production operations. Long before the first board enters the line, you can define program parameters, teach components, generate setup and pick lists, calculate throughput times, and optimize entire production processes.

Virtual production creates reliability, drastically reduces non-productive activities, improves yields, and maximizes SMT line utilization.

Hightopo 2d&3d visualization solution provides visibility across the entire manufacturing pipeline as data is integrated and displayed through smart IoT technologies. It creates a connected, data-driven manufacturing environment that empowers faster problem diagnosis and informed decision-making.