Boring Tools Till – Last Drawer Boxes—Odds & Ends

Jan 1, 2022

A few odds and ends as I built the last two drawer boxes today.

First is one of the steps I don't think I've mentioned in previous write-ups of building a dovetailed box. If the opposing sides of the box are not the same length, it will be very difficult to make a square box. So after cutting the sides, I will match up the opposite sides in my face vise and look at their lengths. If they're uneven, like this pair are, they will need some clean-up.

I do the cleanup with a block plane. In pine, I can take a fairly heavy cut so it goes quickly, and as long as I'm careful, I won't get any spelching. First I go from right to left, tapering off the cut as I go, so I don't remove any material from the left edge.

Then I turn the block plane around, and come from the left edge to the middle, evening things out. If I'm overlapping a little, I won't leave a crown in the middle, but if I do, that's usually not too big of a problem, as I'll clean that up with the final sanding of the drawer.

That done, I dovetail as normal.

For the glue-up, I put glue on the spaces between the pins, and on the sides of the pins.

I slop it on a little heavy. It's a lot easier to clean up a little squeeze-out than it is to have to re-glue a joint.

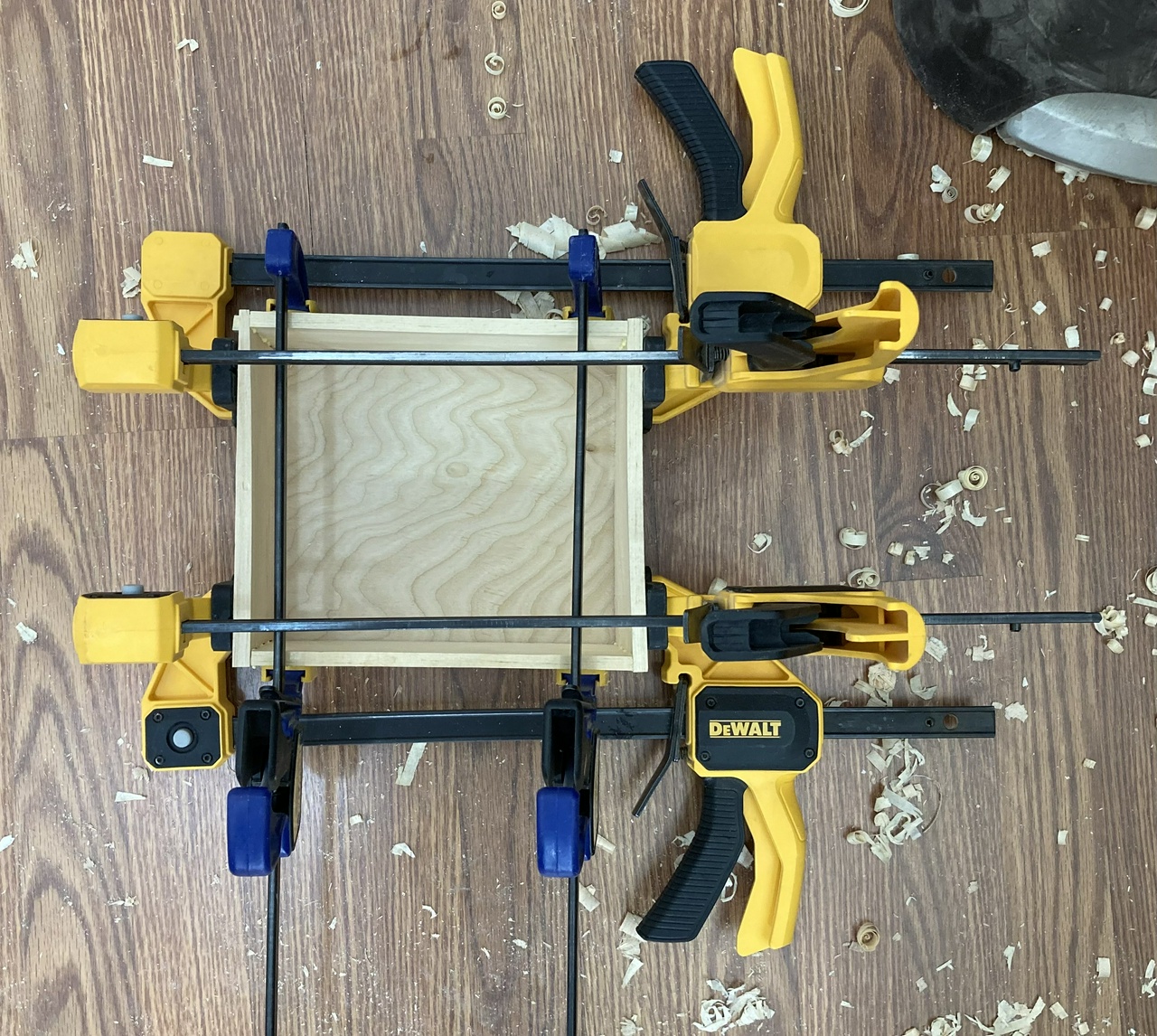

When clamping the box, I put the first clamps on to pull the tails onto the pins, placing the clamps so they're compressing everything against the bottom of the box. If I have made everything fit right, the bottom will still be able to move a bit.

The next clamps go the other direction, holding the sides with the pins tight in the tails.

And then the third set of clamps go on, holding the top of the tail-boards tight on the pins, but not so tight that the boards bow in and end up curvy.

And that's it for today. Happy New Year, and thanks for looking!

Contents #woodworking #storage #drawers

Discuss... Reply to this in the fediverse: @davepolaschek@writing.exchange