I noticed a socket wrench caddy that Jim Jakosh wrote up a while back, and said to myself, “I should make one of those!” This is the result.

The caddy is five-sided, which added a few challenges, mostly getting the box clamped together and aligned while gluing the five sides together. I built flat sides from plywood, with full length glue-blocks on the sides of them to angled “corners” made from cherry.

The cherry corners have various designs on them. I carved running chains of “thumbnails” into one (you can see it to the right of the yellow panel above), and experimented with four different plunge router bits on the other four. Not having a plunge base for my router, I had a few issues, but overall this is a decoration technique I’ll use again.

I initially planned to join the sides to the corners using dowels, but even having built a jig for drilling the holes for the dowels repeatably, I had just enough alignment problems that I couldn’t get everything together, so I cut off the dowels and tried again.

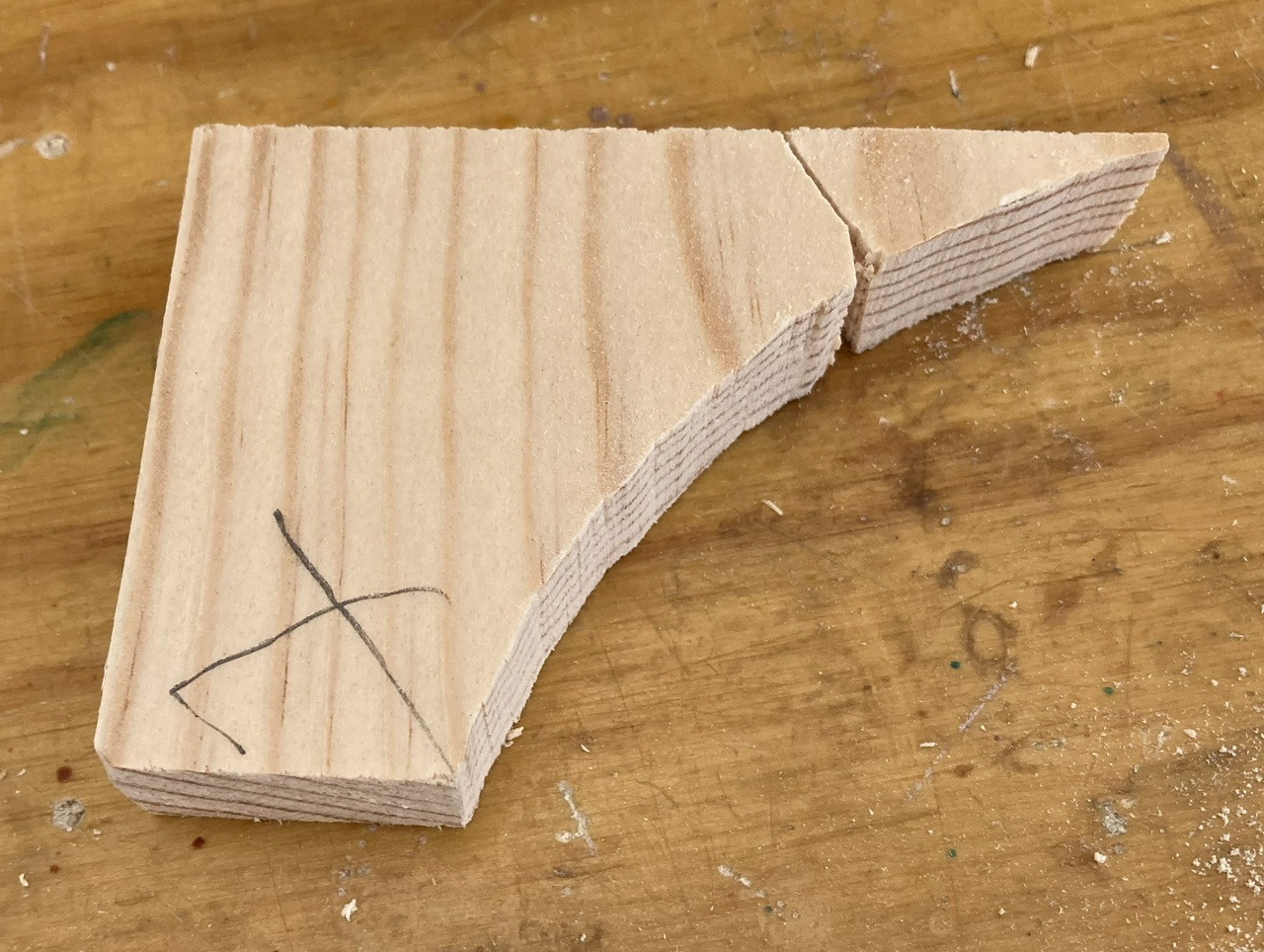

In the end, both the plywood and the cherry had slots cut into them using my table saw (which has a ⅛ inch wide kerf) into which I inserted some ⅛ inch ash veneer (or micro lumber) I have on hand for just this sort of thing.

The ash turned out to be just a little too thick to easily fit into the slots (by about 1/64 inch) so I needed to build a small jig to hold each piece of ash and plane a tiny bit off the surfaces to thin it.

With the splines fitting correctly now, I used some twine string and a couple short pieces of oak to twist them tight to pull the sides and corners together. It worked out pretty well.

That done, I added glue blocks to the top and bottom of the sides to glue the top and bottom of the caddy to, and cut the top from a piece of quartersawn sycamore, with an added purpleheart pentagon, and a smaller apple pentagon to decorate it. While rounding over the purpleheart with the router, I had a couple places where I burned the sycamore with the router bit’s bearing. Oops!

The bottom was just a piece of plywood, with a shallow indentation in it for the lazy susan bearing.

To hold the sockets, I bought three sets of “socket rails”. Once they’re fully populated, the quarter, ⅜ and half-inch drive sockets will be organized into SAE and metric, with two rails on the yellow side for the deep sockets I have in both quarter and ⅜ drive.

I made numerous brackets for the sides of the caddy from 1 inch by 3/32 inch tool steel. Each piece had the appropriate holes drilled into it, then I used a countersink to chamfer the edges of the holes, and then finally bent the bracket in my bench vise, using my 8 oz ball peen hammer.

All of the brackets were laid out and attached to the sides of the caddy before I had assembled it. I attached them all using #6x½ inch brass wood screws, and then removed them all before painting the sides. This gave me pilot holes for all the brackets, and any mistakes had been filled with wood filler and hidden under paint, so things looked good.

The colors are all colors from Real Milk Paint. The red is actually Persimmon, the green is Lily Pad, the blue is Lakeview Blue, and the yellow is Fresh Lemon. They all have a coat of tung oil and two coats of linseed oil applied on top of them.

The final bit of assembly was attaching the base to the bottom of the lazy susan bearing. The trick I figured out for this is that I used machine screws from the bottom of the base (inset into holes) and nuts on top of the bearing. The gap between the base and the bottom of the caddy was just big enough for an open end wrench with a nut taped into it. I only got three of the four screws and nuts together, but if that’s not good enough, I can try to put another screw and nut in. Just not today.

Discuss...

Reply to this in the fediverse: @davepolaschek@writing.exchange